Recommended Reading

- 生物质锌-空气电池Biochar-Based Oxygen Electrocatalysts for Advanced Zn-Air Batteries: Mechanisms, Applications, a...

- 2025中农校庆报告“Renewables Solutions for Our Global Challenges” Keynote Talk at CAU 120th Anniversary

- 2025科学筑梦"Science Builds Dreams • Lights Up the Future" – Sanming, Where My Dreams Started

- 2024院士大会(年会)Prof. Zhen FANG attended 2024 CAE Annual Conference & Induction Ceremony of New Fellows

- 2024国庆Prof. Zhen Fang Invited to the Celebration of the National Day of China in Nanjing

RESEARCH INTERESTS

1.Hydrolysis of lignocellulosic wastes

Fast hydrolysis, low-temperature hydrolysis with catalysts and enzymatic hydrolysis are studied. The sugars produced are biologically converted to biofuels and chemicals (such as bio-hydrogen, ethanol and 2,3 butanediol).

(1) Fast hydrolysis (e.g., 350 oC)

(2) Low-temperature hydrolysis with catalysts (e.g., 150 oC)

(3) Enzymatic hydrolysis (e.g., 50 oC)

2.Synthesis of biodiesel

Heterogeneous nano or magnetic catalysts (such as magnetic carbonaceous acid, calcined/activated hydrotalcite nanoparticles, Na2SiO3@Fe3O4/C, CaFe2O4-Ca2Fe2O5-based catalyst) are produced via different methods (such as co-precipitation, hydrothermal, calcinations, loading).

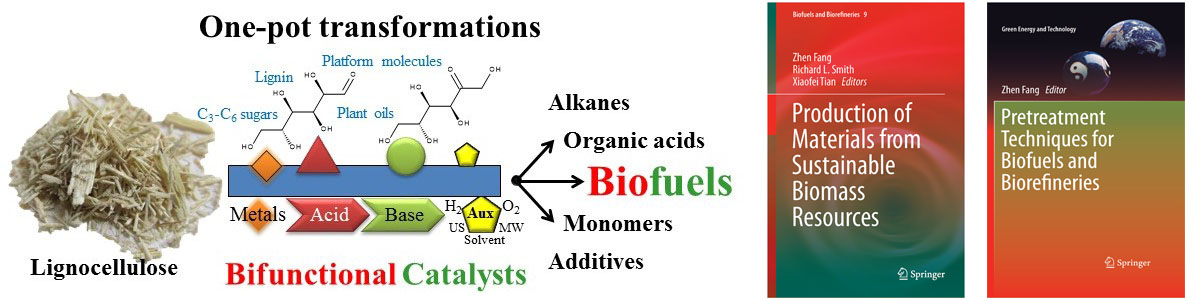

3.Chemical synthesis of value-added products from lignocellulosic wastes

Value-added products (such as 5-hydroxymethylfurfural, biochar, acids, furfural, alkyl levulinates and γ-valerolactone (GVL) etc.) are synthesized in green solvents with acid, base and bi-functional heterogeneous catalysts (such as modified zeolites, ZrO2-zeolite hybrids).

4.Biological production of biofuels from hydrolysates and organic wastes

Biofuels and chemicals (such as bio-hydrogen, ethanol, 2,3 butanediol, lipids) are produced via fermentation of hydrolysates and organic wastes.

5.Thermal conversions of biomass and organic wastes

(1) Fast pyrolysis

(2) Slow pyrolysis for biochar production

(3) H2 production from organic wastes

(4) Supercritical water oxidation (SCW oxidation) of toxic organic wastes

6.Hydrothermally solubilize biomass, and subsequently convert it to biofuels and chemicals

7.Nano or micro catalysts synthesis using hydrothermal method or other conventional ways (e.g., precipitation and calcination)

8.Energy planning and policy, Techno-economic analysis

——————————————

THEORETICAL CONTRIBUTIONS:

Biomass group has made significant contributions to the fields of hydrolysis of lignocellulosic biomass, biodiesel synthesis and liquid biofuel production, supercritical fluid processes, catalyst synthesis and nanomaterials.

1.Pioneered the synthesis of nitrogen-containing compounds and liquid fuels at low temperature from carbohydrates (Nat Commun; PCT/CN2017/106729, PCT/CN2019/098614, 2 CN patents). With or without nanocatalysts, lignocellulose can be almost completely converted into imines and liquid fuels after hydrolysis and decomposition (e.g., 2,5-dimethylfuran, methyl levulinate, γ-valerolactone, methylfuran).

1)Discovery and reaction mechanism of N-formyl quasi-catalytic species

As an important industrial raw material, primary amines have a wide range of applications in medicines, polymers, and functional materials. Generally, primary amines can be prepared by metal-catalyzed reductive amination, but there are problems such as expensive metal catalysts and complicated preparation processes. According to the above problem, we developed a green process for the production of primary amines under catalyst-free and solvent-free condition. Through the study of kinetics, isotope labeling experiment and DFT calculation, it was found that in situ formed N-formyl quasi-catalytic species afford highly selective synthesis of formamides or amines with controllable levels from a variety of aldehyde- and ketone-derived platform chemical substrates (the reaction time can be as short as 3 min). Related results were published: Li, H, Fang, Z.* et al., Nat Commun, 2019, 10, 699; Li, H, Fang, Z.* et al., Green Chem, 2020, 22, 582.)

2.Synthesized nanocatalysts to catalyze the high yield production of liquid biofuels and chemicals (e.g., methyl levulinate, γ-valerolactone, 2,5-dimethylfuran, methylfuran, formamides) at low temperatures directly from carbohydrates (e.g., sugars, cellulose). It is found that 95% 2,5-dimethylfuran yield was obtained from fructose at 110 oC, 99% 2,5-dimethylfuran yield from 5-hydroxymethylfurfural and 97% 2-methylfuran yield from furfural were even achieved at room temperature (25 oC) when polymethylhydrosiloxane was used as H-donor. Therefore, liquid biofuels (e.g., 2,5-dimethylfuran) can be produced from sugars via the hydrolysis of lignocellulosic biomass that is easy for commercial applications in simple and inexpensive reactors.

1)Construction of acid-base bifunctional materials and synergistic catalytic mechanism

Integration of acidic and basic sites is difficult to be compatible in the conventional system into organic-inorganic porous materials through the solvent-thermal self-assembly method to construct an acid-base bifunctional nano-solid material. The bifunctional materials show excellent catalytic activity in the process of acid-base domino/cascade- reaction (hydrogenation-lactonization, sugar isomerization-dehydration reaction) and multivariate reaction (simultaneous esterification-transesterification reaction). It can greatly simplify the reaction process without additional intermediate product separation process.

Related results were published: Li, H, Fang, Z.* et al., Appl Catal B, 2018, 227, 79; Li, H, Fang, Z.* et al., ChemSusChem, 2017, 10, 681; Li, H, Fang, Z.* et al., Appl Catal B, 2017, 200, 182.)

2)Controllable C-C bond coupling technology is the basis for achieving biomass to long-chain alkanes. Aldol reaction is important carbon chain growth reaction in organic synthesis and is often used to structure C-C bonds. By using hydrotalcite-like nanomaterials as precursors, ZnAlLa composite alkaline oxide materials were prepared. Compared with traditional oxides (such as ZnO, ZrO2), the materials can efficiently catalyze the condensation reaction, and the conversion rate of furfural is much higher than that by La2O3. Characterization analysis was found that the excellent performance can be attributed to the structure of La2O2CO3 in the ZnAlLa catalyst and the formation of a large number of La3+-O2- sites.

3.Invented a ‘fast hydrolysis’ process (US patent: 8268126;9115215;9243303;3 CN patent). Wood can be completely dissolved upon fast-heating (7~16 oC/s) to form a ‘wood solution’ at 329-367 oC at short reaction time (0.7-2 s) by adding Na2CO3 in water. The ‘wood solution’ like liquid petroleum can be rapidly (ca. 15 s) hydrolyzed to sugars/sugar oligomers in a liquid phase for subsequent biofuel production (e.g., ethanol) in a flow system. The invention opens the door, for the first time, to the possibility of developing industrial-scale technology at competitive cost for producing biofuels from lignocelluloses based on the ‘fast hydrolysis’ process continuously.

Clarified the reason why lignocellulosic biomass (such as wood) is completely dissolved in subcritical water (Fang Z.*, AIChE J, 54, 2751, 2008).

4.Developed a green process for the production of biodiesel using magnetic solid catalysts instead of conventional liquid catalysts that are unrecoverable. The solid catalysts can be easily separated magnetically for recycles and successfully used for Jatropha biodiesel production. Microwave and ultrasound techniques were also introduced to promote biodiesel production. Our group built up a patented pilot flow reactor for continuous production of biodiesel with the solid catalysts (3-5 t/day, patent license was transferred to a company). (4 CN patent; 20 papers in App Energy, Green Chem, Appl Catal B, Chem Eng J, Energ Convers Manage)

Verified the mechanism of solid alkali catalysts (such as sodium silicate, sodium aluminosilicate, etc.) and microwave and ultrasonic technology that hindered the saponification reaction of free fatty acids and alkalis, catalyzing the production of biodiesel from high acid value waste oil (Related results were published: Zhang F, Fang, Z.* et al., Green Chem, 2016, 18, 3302; Zhang F, Fang, Z.* et al., Energy Convers Manag, 2017, 142, 107; Cong WJ, Fang, Z.* et al., Appl Energy, 2020, 264, 114735).

Explained that by introducing Lewis / Bronsted acid and basic sites, the catalyst has two catalytic active centers at the same time, which can simultaneously catalyze the esterification and transesterification of free fatty acids and triglycerides in high acid value oils to synthesize biodiesel. The process can reduce the reaction steps, reduce energy loss and pollution, and greatly improve the conversion efficiency of high-acid-value oils to produce biodiesel (Related results were published: Wang YT, Fang, Z.* et al., Appl Energy, 2017, 204, 702; Wang YT, Fang, Z.* et al., Chem Eng J, 2018, 348, 929.).

5.Production of aromatic nitrile by pyrolysis of waste polyester plastic with ammonia and its reaction mechanism

Aromatic nitrile is a kind of important industrial raw material, which are widely employed for medicine, polymer and functional material. Reasonable and value-added utilization of waste polyester plastics is very important. We have developed a method of catalytic pyrolysis with ammonia atmosphere to achieve the selective production of terephthalonitrile and benzonitrile from waste polyester plastics, and high purity of aromatic nitriles, and clarified the degradation paths of polyester plastics, and aromatic nitrile C-N bond construction mechanism. Related results were published: Xu L, Fang, Z.* et al., Waste Manag, 2019, 92, 97; Xu, Fang, Z.* et al., Catalysts, 2019, 9, 436.

6.Organic solvent-Lewis acid pretreatment technology was established for the deconstruction and selective separation of lignocellulosic components from agricultural waste straw. The technology realizes the selective separation of a large amount of hemicellulose and lignin without losing cellulose under mild conditions. The mechanism of depolymerization and separation of lignin-carbohydrate complex in biomass, especially the change of lignin macromolecule during pretreatment, was elucidated by the multi-scale characterization of lignocellulosic structure. It provides a theoretical basis for the subsequent lignin recovery and utilization. Related results were published: Tang, S, Fang, Z.* et al., Bioresour Technol, 2019, 294, 122164; Tang, S, Fang, Z.* et al., Bioresour Technol, 2019, 284, 98.

7.Regarding the catalytic conversion of lignocellulosic waste into hydrogen fuel, the following theoretical studies have been carried out. As a green fuel, hydrogen not only has high specific heating value and zero pollution advantages, but also can be converted into a variety of fuels and chemicals. We use modified 10Ni / Al2O3 catalysts with different Co loadings to catalyze the hydrothermal gasification of lignocellulosic waste to produce hydrogen, which improved the hydrogen yield and realized the utilization of lignocellulosic waste. Related results were published: Sun, J, Fang, Z.* et al., J Supercrit Fluids, 162, 104863, 2020. The reason for high gasification rate is clarified: sub/supercritical water has low dielectric constant and large ion product, which is conducive to the dissolution and hydrolysis of lignocelluloses in water, and the low viscosity and large diffusion coefficient are conducive to the acceleration of mass transfer rate, thereby promoting chemical reaction. It catalyzed the hydrothermal gasification of cotton straw to produce H2 with 82.6% yield by synthesized Co-Ni / Al2O3 catalyst. This is due to the formation of Ni-Co alloy in the Co-Ni / Al2O3 catalyst, which improves the gasification performance of the catalyst and enhances the ability of the catalyst to resist carbon deposition, avoiding the rapid deactivation of the catalyst caused by carbon deposition in catalyst.

8.As editor-in-chief, Springer Book Series – Biofuels and Biorefineries (https://www.springer.com/series/11687), Prof. Fang leads editorial board composed of eight world-leaders in biofuels and biorefineries (2 NAE members, 4 FCAE, 1 FRS and a famous professor at Tohoku university in Japan). The purpose of this series is to organize bioenergy experts around the world to publish a series of books related to biomass in different fields, aimed at the publication of at least two volumes per year. The book series will be focusing on introducing knowledge, research and recent exhibitions all aspect related with biomass production, biofuels, bioproducts, chemicals, biomaterials, food and pharmaceutical products, energy planning and policy, as well as processing technologies. The book series will be the powerful and integrative source of biomass, bioenergy, biofuels, bioproducts and biorefinery for scientists, students, policy maker and engineers to reflect the explosive growth in this interdisciplinary area.

At present, Prof. Fang has published 19 English books (12 Springer books with 350k chapter downloads). The series has published 10 monographs, with 170k chapter downloads, one book wins 2020 “Springer-Nature China New Development Awards” in recognition of his exceptional contributions to the delivery of the UN Sustainable Development Goals. Four books are among the “top 25% springer e-books”.

This book series has become the knowledge library of the latest progress and theoretical innovation of bioenergy studies and applications.

理论创新:

生物能源组在木质纤维素水解、生物柴油合成、液体生物燃料生产、超临界流体工艺、催化剂合成和纳米材料等领域做出了重大贡献。

1.开创了从碳水化合物中低温合成含氮化合物和液体燃料 (Nat Commun; PCT/CN2017/106729, PCT/CN2019/098614, 2项中国专利)。无论有没有纳米催化剂,木质纤维素水解和分解后几乎可以完全转化为亚胺和液体燃料(2,5-二甲基呋喃、乙酰丙酸甲酯、γ-戊内酯、甲基呋喃)。

N-甲酰基准催化物种的发现及反应机制. 伯胺作为重要的工业原料,在药物、聚合物、功能材料等方面具有广泛的应用价值。通常,伯胺可通过金属催 化还原胺化反应制备得到,但存在金属催化剂价格昂贵、制备过程较复杂等问题。针对上述问题,我们开发了一 种全新的在无催化剂和溶剂的条件下合成伯胺的绿色方法,通过动力学、同位素标记实验以及 DFT计算等研究发 现原位形成的 N-甲酰基作为准催化物种,可促进并调控一系列生物质基醛和酮化合物高选择性甚至定量转化为甲 酰胺或胺(反应时间可短至 3 min)。相关工作发表在:Li, H, Fang, Z.* et al., Nat Commun, 2019, 10, 699; Li, H, Fang, Z.* et al., Green Chem, 2020, 22, 582. )

2.合成纳米催化剂,在低温条件下直接催化碳水化合物(例如糖,纤维素)高产率生产液体生物燃料和化学品(例如乙酰丙酸甲酯,γ-戊内酯,2,5-二甲基呋喃,甲基呋喃)。研究发现在110 oC条件下果糖中获得2,5-二甲基呋喃的产率为95%,在室温条件(25 oC),以聚甲基氢硅氧烷作为氢供体时,可以从5-羟甲基糠醛中获得99%的2,5-二甲基呋喃产率和糠醛中97%的2-甲基呋喃产率。因此,可以通过木质纤维素的水解糖生产液体生物燃料(例如2,5-二甲基呋喃),这方法易于在简单且廉价的反应器中进行商业应用。

酸-碱双功能材料的构筑及其协同催化机制. 将常规体系中难兼容的酸性和碱性位点,通过研发的热液自组装手段,整合到有机-无机多孔材料上,构筑出兼具酸-碱位点的双功能纳米固体材料;该类双功能材料在酸-碱级联反应(氢化-内酯化、糖异构化-脱水反应等)和多元反应(同时酯化-酯交换反应等)过程中,表现出优异的催化活性,且可大大简化反应工艺、无需额外中间产物分离过程等。相关工作发表在:Li, H, Fang, Z.* et al., Appl Catal B, 2018, 227, 79; Li, H, Fang, Z.* et al., ChemSusChem, 2017, 10, 681; Li, H, Fang, Z.* et al., Appl Catal B, 2017, 200, 182.)。

可控的C-C键偶联技术是实现生物质到长链烷烃的基础. 羟醛缩合是有机合成中重要的碳链增长反应,常用于架构C-C键。通过以类水滑石纳米材料为前驱体,制备ZnAlLa复合碱性氧化物材料,该材料相较于传统的氧化物(如ZnO,ZrO2等)能够高效催化缩合反应,并且糠醛转化速率远高于La2O3。通过表征分析发现,优异的性能可归因于ZnAlLa催化剂中La2O2CO3结构以及大量La3+-O2-位点的形成。

3.发明“快速水解”技术 (美国专利号:8268126;9115215;9243303;3 CN专利)。在水中添加Na2CO3到木材生物质颗粒(或木质纤维素生物质)中,木材再快速升温(7~16 oC/s)至329-367 oC下,可在0.7~2 s内完全溶解形成“木材溶液”。在流动系统中,类似于液态石油的“木液”可以在液相中快速水解成糖/糖低聚物,用于随后生物燃料的生产(如乙醇)。此发明第一次打开了,具有竞争力的成本开发工业规模, 基于“快速水解”过程连续地从木质纤维素,生产生物燃料可能性。

阐明了木质纤维素生物质(如木材)在亚临界水完全溶解的原因(Fang Z.*, AIChE J, 54, 2751, 2008).)。

4.开发了出绿色工艺,使用磁性固体催化剂代替无法回收的常规液体催化剂生产生物柴油。固体催化剂可以很容易地通过磁力分离进行再循环,并成功用于小桐子生物柴油的生产。并且引入了微波和超声技术来提升生物柴油的生产。团队发明了一种中试流动反应器,利用固体催化剂连续生产生物柴油(3-5吨/天,该设备专利已转让给公司)。(4项中国专利; 20 papers in App Energy, Green Chem, Appl Catal B, Chem Eng J, Energ Convers Manage).

阐明固体碱催化剂(如:硅酸钠、硅铝酸钠等)以及微波和超声技术阻碍自由脂肪酸与碱发生皂化反应的,催化高酸值废弃油脂制备生物柴油的机制(相关工作发表:Zhang F, Fang, Z.* et al., Green Chem, 2016, 18, 3302; Zhang F, Fang, Z.* et al., Energy Convers Manag, 2017, 142, 107; Cong WJ, Fang, Z.* et al., Appl Energy, 2020, 264, 114735)。解释了通过引入Lewis/Bronsted 酸和碱性位点,使催化剂同时具备两种催化活性中心,可同时催化高酸值油脂中的自由脂肪酸和甘油三酯发生酯化和转酯化反应合成生物柴油,该工艺可缩减反应步骤、减少能量损耗和污染、大大提高了高酸值油脂制备生物柴油的转化效率(相关工作发表:Wang YT, Fang, Z.* et al., Appl Energy, 2017, 204, 702; Wang YT, Fang, Z.* et al., Chem Eng J, 2018, 348, 929.)

5.废弃聚酯塑料热解氨化资源化制备芳香腈及其反应机制. 芳香腈是一类重要的工业原料,在药物、聚合物、功能材料等方面具有广泛的应用价值。废弃聚酯塑料是目前生活中大宗的废弃塑料,对其合理和增值化利用非常重要。我们开发了通过氨气氛围催化热解的方法实现废弃聚酯塑料选择性制备对苯二甲腈和苯甲腈两种化学品,并可以实现芳香腈的高纯度提纯和明确聚酯塑料降解途径和芳香腈 C-N键构筑机制,为实现废弃化合物的高附加值资源化利用和芳香睛化学品的绿色生产的提供一条可能的 反应途径。相关工作发表在:Xu L, Fang, Z.* et al., Waste Manag, 2019, 92, 97; Xu, Fang, Z.* et al., Catalysts, 2019, 9, 436.

6.以农业废弃秸秆为原料,针对木质纤维素解构及组分选择性分离,我们建立了有机溶剂-路易斯酸预处理技术。该 技术实现在了温和条件下,不损失纤维素的同时,选择性分离出大量半纤维素和木质素。并通过木质纤维素结构 上多尺度表征, 阐明了生物质中木质素-碳水化合物复合物的解聚分离机制,尤其是预处理过程中木质素大分子的 变化,为后续木素回收利用提供了理论基础。相关工作发表在:Tang, S, Fang, Z.* et al., Bioresour Technol, 2019, 294, 122164; Tang, S, Fang, Z.* et al., Bioresour Technol, 2019, 284, 98。

7. 围绕木质纤维素废弃物催化转化为氢气燃料,开展了如下理论研究:氢气作为一种绿色燃料, 不仅具有高的比热值和零污染优点,还可以转化为多种燃料和化学品。我们利用不同 Co负载量改 性 10Ni/Al2O3催化剂,用于催化木质纤维素废弃物水热气化制取氢气,不仅提高了氢气产率还实现 木质纤维素废弃物的资源化利用。相关工作发表:Sun, J, Fang, Z.* et al., J Supercrit Fluids , 162, 104863, 2020.

阐明了高气化率的原因: 亚/超临界水具有低的介电常数和大的离子积这有利于木质纤维素废弃物在水中进行溶解和水解,且低的粘度和大的扩散系数有利于加快传质速率,从而促进化学反应。所合成的Co-Ni/Al2O3催化剂催化棉花秸秆水热气化的H2产率可以达到82.6%这是由于Co-Ni/Al2O3催化剂中形成了Ni-Co合金,提高了催化剂的气化性能,且增强了催化剂抗积碳的能力,避免了催化剂在反应中因积碳引起的快速失活。

8.农林废弃生物质资源化不仅可以减少废弃物对环境的污染而且是我国改善能源结构的现实需求。生物质预处理是木质纤维生物质生物炼制的第一步,直接决定了后续炼制过程的效率和产量。在以二元醇为溶剂的生物质预处理过程中,二元醇在木质素a位的醚化反应为木质素引入“羟基尾巴”。虽然a位的醚化反应已被证实可以抑制木质素的缩合,但是由于其与木质素的解聚反应是竞争反应,在有机溶剂预处理的过程中会降低木质素的分离效率。我们研究发现二元醇预处理引入的“羟基尾巴”直接增加木质素与二元醇氢键溶剂参数的相似度,不仅可以抑制预处理过程中木质素的缩合,还可以提高木质素的溶解度,使木质素的溶出率提高10%,结构完整度提高20%。

9.方老师作为Springer系列丛书“生物燃料和生物炼制” 创始总编辑,他负责的编委会,由八位世界著名的生物燃料和生物炼制专家组成(两位美国工程院院士,四位加拿大工程院院士,一位加拿大皇家学会院士和一位日本东北大学著名教授)。该系列丛书的目的是组织世界各地的生物能源专家出版一系列在不同领域与生物质相关的书籍,旨在每年至少出版1-2册专著。该系列丛书将着重于介绍与生物质生产,生物燃料,生物制品,化学品,生物材料,食品和医药产品,能源规划和政策,以及加工技术相关的所有方面的知识,研究和近展。该系列丛书将是强大的和综合的有关生物质生产,生物能源,生物燃料,生物制品的知识库。为科学家,学生,政策制定者和工程师提供知识以反映生物炼制这个交叉学科领域研究的爆炸性增长并引导该学科的发展。

目前,方老师发表英文专著20部(Springer 13部,38万次章节下载量)。该系列丛书出版10部专著,章节的许多作者或审稿人为(或成为)中国和发达国家院士或著名期刊的总编辑,章节下载量(电子版销售量)18万次。其中一本书赢得了2020年“斯普林格-自然中国新发展奖”,以表彰他对实现联合国可持续发展目标(SDGs)的杰出贡献。他编著的4 部专著已进入Springer高下载书籍前25%。该系列丛书已成为生物燃料研究最新进展和理论创新的知识库,它大大增加了中国和加拿大在可再生能源领域研究的影响力。

------------------

生物能源组研究方向:

转化农业和生物质废弃物为高附加值的燃料,化学品和生物制品。具体研究内容包括如下:

(i)、绿色溶剂(冷冻冰晶、水热水、离子液体、有机电解液、超临界流体等)的研发与应用(预处理和生物燃料合成),双功能催化剂合成及用于催化生物质生产液体燃料和化学品等;

(ii)、水热转化(快速水解纤维素、木质纤维素生产可发酵糖、有机酸和化学品等;水热气化),热解和燃烧技术和装置的开发与应用;

(iii)、微生物发酵法转化木质纤维素水解产物生产油脂(生物柴油)、醇、酮、有机酸、氢气和沼气及其它次级代谢产物,微生物发酵法转化副产品甘油生产乳酸、丙二醇等化学品;

(iv)、纳米和固体催化剂的制备及应用,包括催化植物油制备生物柴油、预处理和催化木质纤维素水解并生产可发酵糖、合成化学品和生物燃料等;

(v)、能源政策和规划,能源系统优化和评价。

Copyright © 2018 BIOMASS GROUP, NANJING AGRICULTURAL UNIVERSITY All Rights Reserved 登录