响应面优化丁酸梭菌培养基并用于发酵热带植物废弃物水解液制备氢气

氢气作为一种清洁和可再生能源,生物制氢技术与其他制氢方法相比,具有无污染、成本低、可再生等优点,因此,生物制氢技术的研究受到广泛关注。

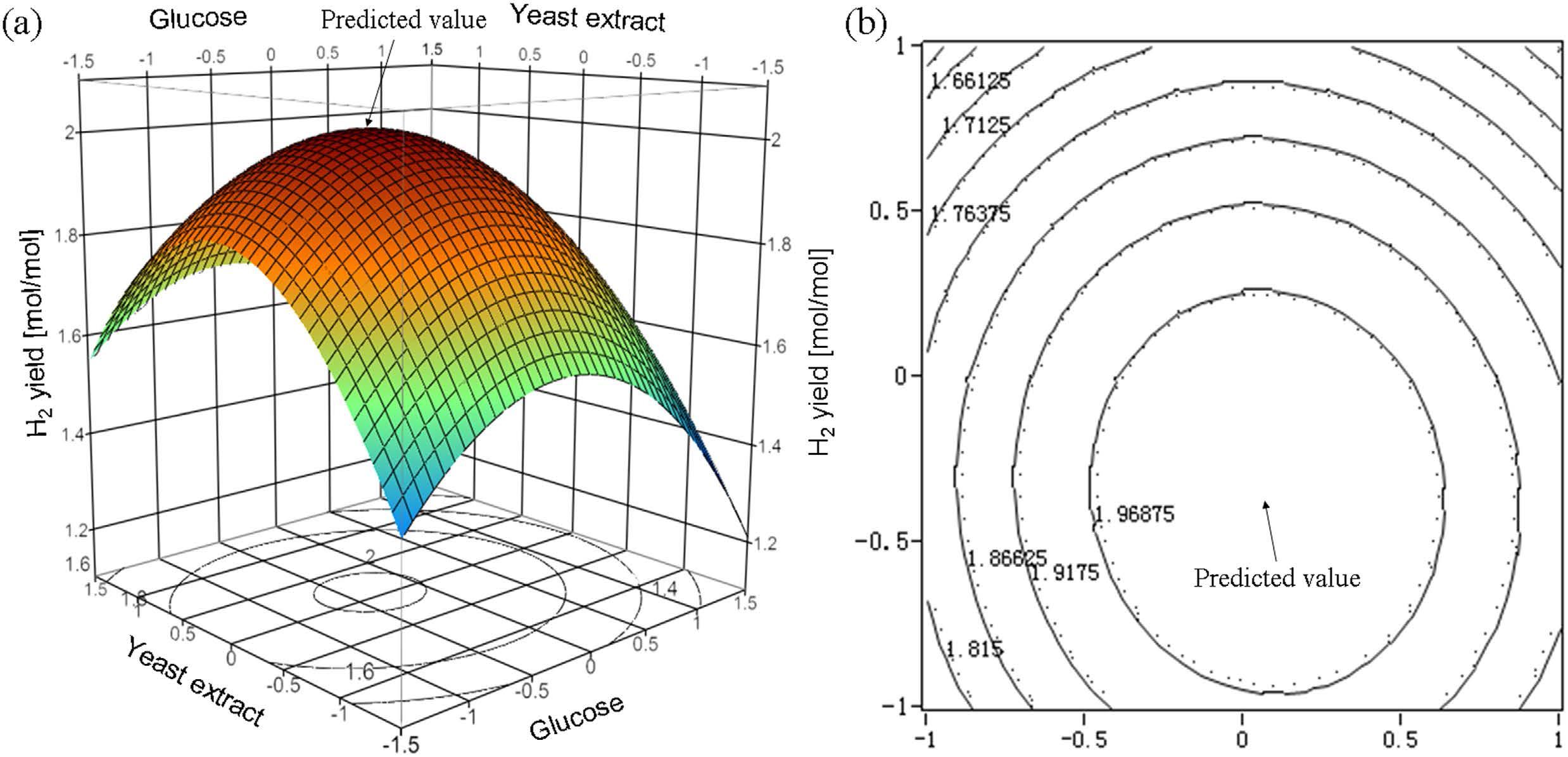

生物能源组研究人员通过响应面优化丁酸梭菌的发酵培养基,并运用发酵热带植物废弃物水解液制备氢气。此项工作表明,当丁酸梭菌的发酵培养基为(g/L):15.66 葡萄糖, 6.04 酵母粉, 4 蛋白胨, 3 K2HPO4, 3 KH2PO4, 0.05 L-cysteine, 0.05 MgSO4·7H2O, 0.1 MnSO4·H2O 和0.3 FeSO4·7H2O时氢气产率可达到最优值(2.02 mol H2/mol葡萄糖)。甘蔗渣和小桐子果壳作为热带生物质废弃物经过两步稀酸水解后得到可用于发酵的还原糖。在最优培养基条件下,分别以甘蔗渣和小桐子果壳水解液代替葡萄糖作为碳源,丁酸梭菌的氢气产率达到2.06 mol H2/mol总还原糖(甘蔗渣)和1.95 mol H2/mol总还原糖(小桐子果壳)。其中氢气含量为49.7–64.34%。该研究为丁酸梭菌制备氢气的研究提供了一个较优的培养基组分,此外为进一步利用生物质废弃物制备氢气的研究提供了有效的方法。

详情可见:

D Jiang,Zhen Fang*, SX Chin, XF Tian, Biohydrogen Production from Hydrolysates ofJatrophaHulls and Sugarcane Bagasse withClostridium Butyrium,Scientific Reports, 6:27205(2016).

———————————————————————

Biohydrogen Production from Hydrolysates of Selected Tropical Biomass Wastes withClostridium Butyricum

Hydrogen can serve as a clean and renewable energy resource. In comparison with of existing methods of hydrogen production, biohydrogen (or biological hydrogen) production technology possesses advantages, such as pollution-free, lower cost, and renewable.

Biomass group successfully optimized the fermentation medium ofClostridium Butyricumby response surface methodology, and produced hydrogen from hydrolyzates of selected tropical biomass wastes under the optimal condition.

In their work, highest H2yield of 2.02 mol H2/mol-glucose was achieved, while the composition of medium was (g/L): 15.66 glucose, 6.04 yeast extract, 4 tryptone, 3 K2HPO4, 3 KH2PO4, 0.05 L-cysteine, 0.05 MgSO4·7H2O, 0.1 MnSO4·H2O and 0.3 FeSO4·7H2O. Sugarcane bagasse andJatrophahulls were selected as typical tropical biomass wastes to produce sugars via a two-step acid hydrolysis for hydrogen production. Under the optimized fermentation conditions, H2yield (mol H2/mol-total reducing sugar) was 2.15 for glucose, 2.06 for bagasse hydrolysate and 1.95 forJatrophahulls hydrolysate in a 3L fermenter for 24 h at 35 °C, with H2purity of 49.7–64.34%. The results provide useful information and basic data for practical use of tropical plant wastes to produce hydrogen.

The study was published:

D Jiang,Zhen Fang*, SX Chin, XF Tian, Biohydrogen Production from Hydrolysates of Jatropha Hulls and Sugarcane Bagasse withClostridium Butyrium,Scientific Reports, 6:27205(2016).

(a) Response surface plot and (b) corresponding contour of the mutual effects of glucose and yeast extract on H2yield (24 h bottle fermentation at 35 °C with 130 rpm shaking).