“Fast dissolution of cellulose for hydrolysis” was authorized US patent

Recently, “fast dissolution of cellulose for hydrolysis” invented byProf. Zhen Fangwas authorized US patent (US patent#: 9115215; issue date: 08/25/2015).

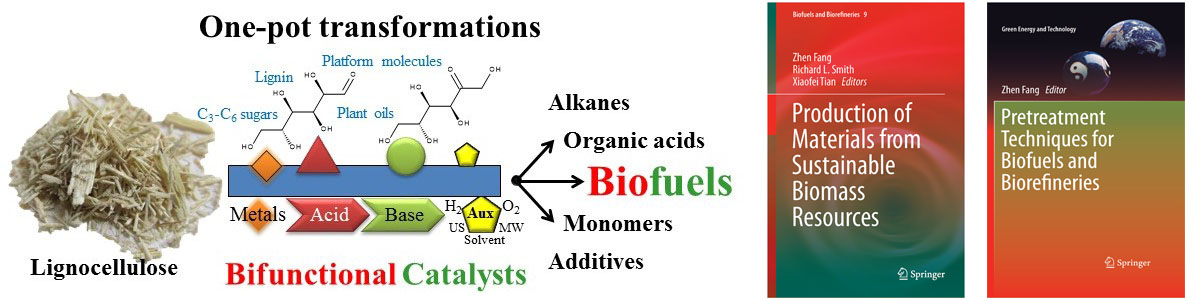

In the nature, lignocellulosic biomass, such as wood and grass, is roughly consisted of 50% cellulose, 25% hemicellulose, and 20% lignin. Cellulose can be hydrolyzed into saccharides which are further used for producing cellulosic ethanol through fermentation. Because lignocellulosic biomass is water-insoluble, the current industrial methods for hydrolyzing biomass proceed mainly in a semi-continuous percolating reactor containing 0.4~0.8% dilute aqueous sulphuric acid, at temperature of 180~190℃ and under pressure of 12~14 atmospheres. Reports about continuous production of sugars in a high-pressure continuous flow reactor were not found.

Prof. Fanginvented a method for completely dissolving and rapidly hydrolyzing cellulose, and uses thereof.

Cellulose is placed in an acidic aqueous solution with a [H+] concentration of 10-7~1Mor an alkaline aqueous solution with a [OH–] concentration of 10-7~1Mas sample A, wherein the volume ratio of solid to liquid is (0.003~05).

The acidic aqueous solution with a [H+] concentration of 10-7~1Mor the alkaline aqueous solution with a [OH–] concentration of 10-7~1Mis heated up to 261~352℃ as sample B.

Sampe A and sample B obtained from step 1 and step 2 are mixed in a reactor to a concentration of cellulose of 0.1%~35%, the concentration of the mixed solution is adjusted to an acidity of 10-7~1M[H+] or an alkalinity of 10-7~1M[OH–], and a water density of 587~997 kg/m3, pressure is set at 6~584 MPa. The mixture is rapidly heated up to 261~352℃ at heating rate of 7.8~8℃/s, and then cellulose is dissolved completely in 0.8~2 sec and hydrolyzed in 5 sec.

Using this technique, it is the first time for achieving complete dissolution and rapid hydrolysis of cellulose at a lower temperature, which not only dramatically reduces the cost of hydrolysis but also improves the safety of production and extends the service life of equipment in a flow system, thus possessing a good application prospect.

一种完全溶解和快速水解纤维素的方法及其应用获美国专利

自然界中的木质纤维素生物质如木材和草类,大约是由50%的纤维素,25%的半纤维素和20%的木质素组成。纤维素经水解能够降解为糖类,进而用于发酵生产纤维素酒精。由于木质纤维素生物质不溶于水,现有的工业化生物质水解方法主要是以半连续式渗透反应器、在180~190℃和12~14 大气压下的0.4~0.8%稀硫酸水溶液中水解。未见使用高压连续反应器进行连续生产的报道。

方真研究员在深入研究后发现,在溶解和快速水解纤维素之前,先将其置于酸性或碱性溶液中,然后再将得到的混合物与高温稀酸或稀碱溶液混合,并以一定的加热速率加热至一定的温度,则可以实现纤维素的完全溶解和快速水解。在此基础上,发明人提出如下技术方案:

一种完全溶解和快速水解纤维素的方法,包括以下步骤:

1、将纤维素置于浓度为10-7~1M[H+]酸性或10-7~1M[OH–]碱性水溶液中,固液体积比为(0.003~1.05):1;

2、将10-7~1M[H+]酸性或10-7~1M[OH–]碱性水溶液加热至261~352℃;

3、混合步骤1和2所得物置于反应器中,纤维素浓度为0.1%~35%,调节混合后的物料溶液浓度为10-7~1M[H+]酸性或10-7~1M[OH–]碱性,水密度为587~997 kg/m3,设定压力为6~584 MPa,加热速率为7.8~14.8℃/s,快速加热至261~352℃,0.8~2秒即能完全溶解纤维素。

溶剂化的纤维素可以很方便地应用于低温的高压流动式的反应器,进一步降低了生产成本,连续水解生产糖类及别的生物燃料和产品。

该发明获美国专利(US patent#: 9115215; issue date: 08/25/2015)。