Coproduction of Furfural and Easily Hydrolyzable Residue from Sugar Cane Bagasse

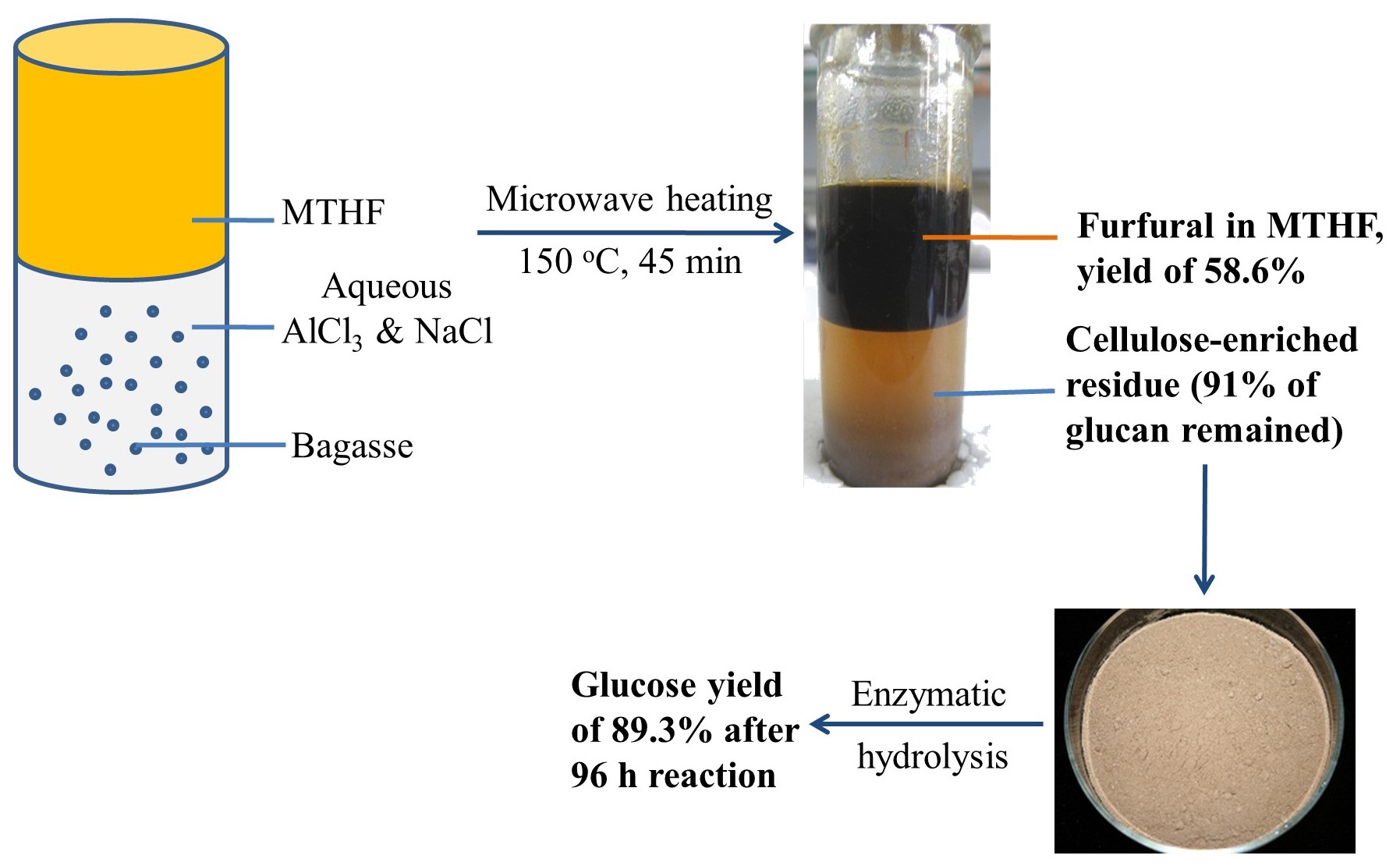

In order to develop a process for the simultaneous production of furfural and easily hydrolyzable cellulose, the degradation of sugar cane bagasse in a single aqueous system and in a 2-methyltetrahydrofuran (MTHF)/aqueous AlCl3biphasic system was studied.

Biomass group successfully produced furfural and easily hydrolyzable residue from sugar cane bagasse. In single aqueous system, the influence of acid species (FeCl3, HCl, and AlCl3) on furfural production and cellulose degradation was investigated at 150 °C. FeCl3and HCl promoted furfural production from hemicellulose but with severe cellulose degradation. AlCl3decreased cellulose degradation with considerable furfural yield and high glucan content in solid residues. The role of NaCl in furfural production and cellulose decomposition was also investigated in the single aqueous system using different acids as catalysts. Addition of NaCl significantly promoted furfural yield but also accelerated cellulose decomposition when FeCl3or HCl was used as catalyst. In the AlCl3-catalyzed system, NaCl had less influence on residue yield and its composition, although NaCl also promoted furfural production. The influence of MTHF on furfural yield, residue composition, and enzymatic hydrolysis of residue was also studied. Under the best conditions (0.45 g of bagasse, 9 mL of MTHF, 9 mL of water, 0.1 M AlCl3, 150 °C, 45 min, and 10 wt % NaCl), 58.6% furfural was obtained while more than 90% of cellulose remained in the residue. The organic phase was separated from the aqueous phase directly by decantation. After reuse of organic phase for 3 cycles, 11.5 g/L furfural was obtained. The catalyst-containing aqueous phase could be reused directly after decantation of the organic phase without loss of activity. The obtained residue was easy to hydrolyze and produced 89.3% glucose yield after 96-h enzymatic hydrolysis at low cellulase loading (30 FPU of cellulase/g-glucan).

The study was published:

XK Li, Zhen Fang*, et al., Coproduction of Furfural and Easily Hydrolyzable Residue from Sugar Cane Bagasse in the MTHF/Aqueous Biphasic System: Influence of Acid Species, NaCl Addition, and MTHF, ACS Sustainable Chemistry & Engineering,4, 5804−5813 (2016).

Furfural (58.6% yield) and cellulose-enriched residue (>90% glucan recovered) are coproduced with 89.3% glucose yield in a MTHF/aqueous AlCl3system.

从甘蔗渣中生产糠醛和易水解残渣

为了开发生产糠醛和容易水解纤维素的生产工艺,对甘蔗渣在单一水相体系和 2-甲基四氢呋喃 (MTHF)/ AlCl3水溶液双相体系进行了研究。生物能源组成功地从甘蔗渣中生产糠醛和易水解残渣。

在单一水相体系和 150 °C条件下,对酸的种类(FeCl3、 HCl 和 AlCl3)生产糠醛和纤维素降解的影响进行了研究。FeCl3和HCl 促进半纤维素生产糠醛,而严重地引起纤维素的降解。AlCl3可减少降解植物纤维素,并产生相当数量的糠醛产量和高含量的葡聚糖的固体残留物。使用不同的酸作为催化剂,在单一水相体系中考察了 NaCl 在糠醛生产和纤维素分解中的作用。当用FeCl3或盐酸作为催化剂时,添加NaCl 有力地促进糠醛产量,但也加速了纤维素分解。在 AlCl3催化体系中,NaCl对残留物产量和其组成影响较小,尽管NaCl 也促进了糠醛生产。MTHF对糠醛产量、 残留物的组成及其酶水解进行了研究。在最佳条件下(0.45 g蔗渣,9 毫升 MTHF,9 毫升的水、 0.1 M AlCl3、 150 °C、 45 分钟和 10 wt % NaCl),可获得58.6%的糠醛和超过 90%的纤维素留存在残渣中。有机相可从水相直接分层而得到并循环利用。有机相循环3次后,可得到 11.5 g/L 糠醛。有机相分离后,包含催化剂的水相没有失去活性,可以直接重复使用。

所得的残渣很容易水解, 96 h酶水解后,葡萄糖产率为 89.3% (30 FPU纤维素酶/g-葡聚糖)。

该研究发表于︰

XK Li, Zhen Fang*, et al., Coproduction of Furfural and Easily Hydrolyzable Residue from Sugar Cane Bagasse in the MTHF/Aqueous Biphasic System: Influence of Acid Species, NaCl Addition, and MTHF, ACS Sustainable Chemistry & Engineering,4, 5804−5813 (2016).