Climate change and rising oil prices have urged the needs for researching alternative energy. Among possible alternative resources, lignocellulosic biomass is one of the promising raw materials, which has been intensively studied recently.Lignocellulosic materials consist of cellulose, hemicellulose and lignin. The different sources and type of lignocellulosic materials such as agricultural wastes/residues, wood, water plants, etc., are well known as a starting material for various chemicals feedstocks, such as bioethanol and biofuel.

In Malaysia, about 17 million tons of oil palm EFB is produced from the palm oil extraction process every year. Oil palm EFB fibres compose of about 40% cellulose 30% hemicellulose, and 22% lignin. Among potential lignocellulosic materials in Malaysia, oil palm EFB fibre is one of the most potential resources due to its abundant availability and low cost. Chemical components in oil palm EFB fibres, particularly the cellulose and hemicellulose, can be converted into fermentable sugars via acid or enzymatic hydrolysis and other basic chemicals. C5 sugars can be hydrolyzed and decomposed into furfural and other chemicals, while C6 sugars can be converted into 5-hydroxymethyl-furfural (5-HMF), levulinic acid (LA), formic acid, etc.

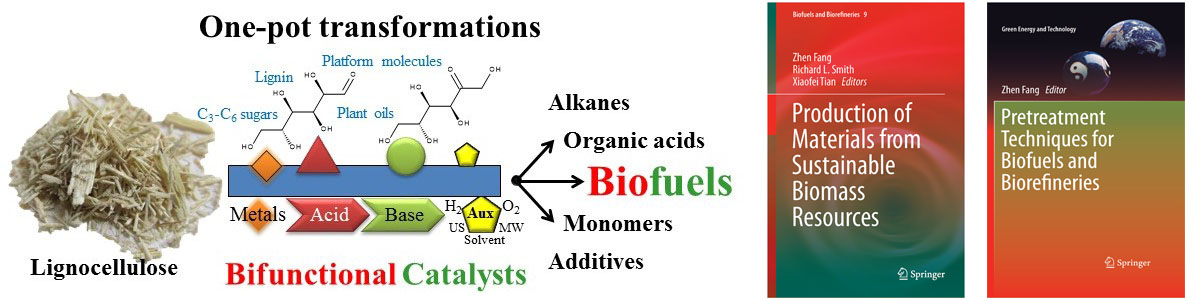

Miss Siew-Xian-Chin, a PhD student, co-supervised by Dr. Chin-hua CHIA (National University of Malaysia) and Prof. Zhen FANG (Biomass Group, Xishuangbanna Tropical Botanical Garden, CAS) successfully used oil palm EFB as raw material for kinetic study of acid hydrolysis of EFB fibres into different chemical components. This is a useful approach to understand the pathway and rate of hydrolysis process.

The aim of this work is to investigate the effect of reaction temperature (120-180°C) and sulfuric acid concentration (0.25-0.5 N) on the hydrolysis of oil palm EFB fibres into different products using a well-controlled microwave reactor to provide further insights into the acid hydrolysis mechanism of EFB fibres into different fine chemicals. A series of first order reactions model was used to develop the kinetic study of the acid hydrolysis of EFB fibres. The hydrolysis kinetics of the main intermediates, such as sugars (glucose and xylose), 5-HMF, LA, and acetic acid, was found to be dependent on temperature and acid concentration. The highest yield of xylose, glucose, 5-HMF, LA, and acetic acid are 11.21 g/L, 10.03 g/L, 0.50 g/L, 9.27 g/L, and 4.36 g/L, respectively. These kinetic parameters provide useful information and basic data for the practical use of EFB fibres to produce fine chemicals.

The study entitled “A Kinetic Study on Acid Hydrolysis of Oil Palm Empty Fruit Bunch

Fibers Using a Microwave Reactor System” has been published in Energy & Fuels, 2014, 28: 2589-2597, http://pubs.acs.org/doi/abs/10.1021/ef402468z