Direct production of biodiesel from renewable oils using calcined blast furnace dust

Recently, Dr Ms. Yi-Tong Wang (Associate Professor, College of Metallurgy and Energy, North China University of Science and Technology) and Prof. Zhen Fang published an article in Renewable Energy using calcined blast furnace dust as catalyst material for biodiesel production.

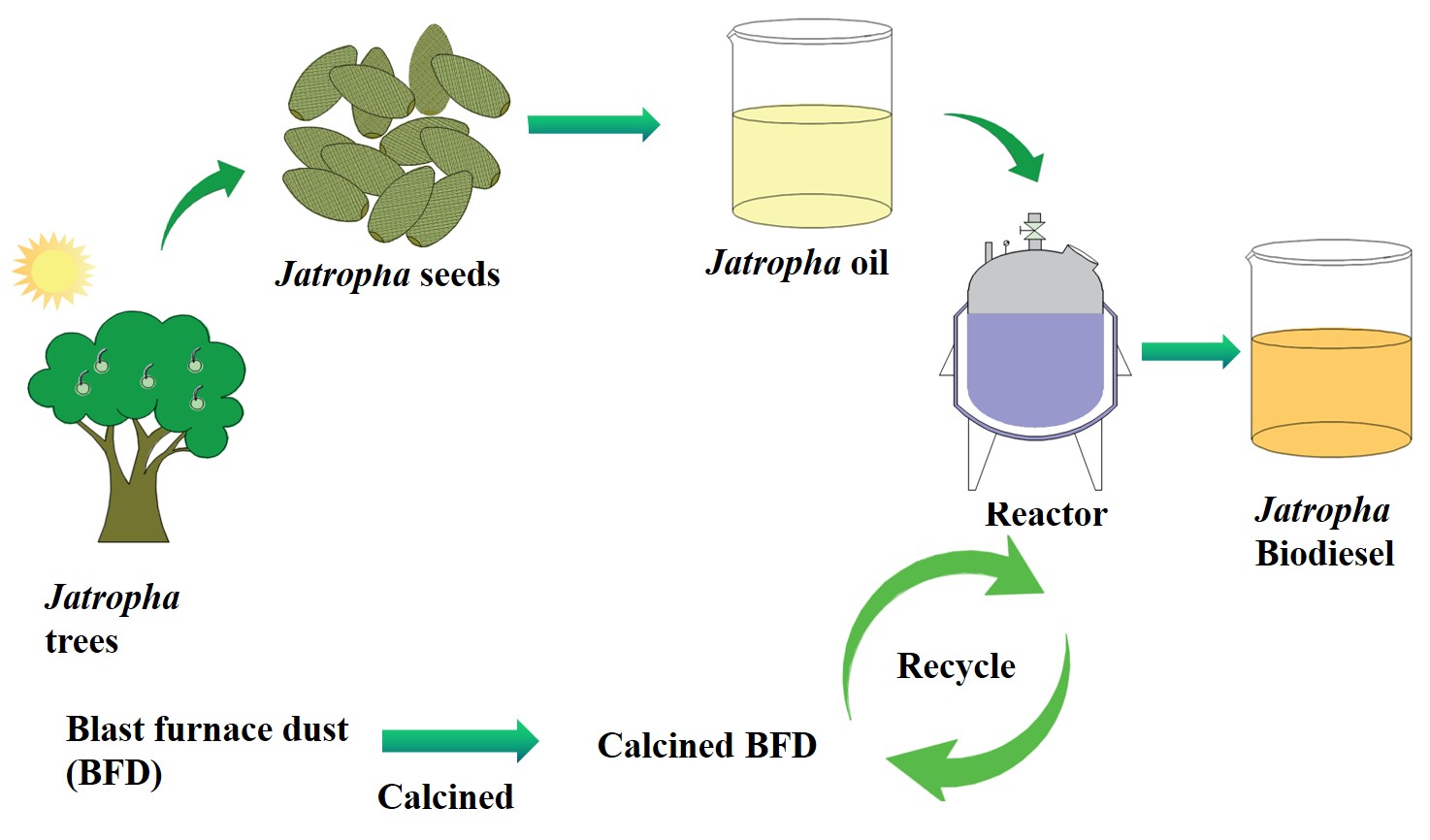

Direct production of biodiesel by both esterification and transesterification of renewable oils with acid value (AV) of 9.6-28.9 mg KOH/g using calcined blast furnace dust is studied. Blast furnace dust calcined at 600-700 oC obviously promotes efficient biodiesel production because of the crystal form transformation from lead sulfate particles in dust into active lead oxide, lead sulfide, and lead particles. It is found for the first time that lead oxide, lead sulfide and lead particles can resist saponification from fatty acids to catalyze raw renewable oils to biodiesel with catalytic activity order as follows: lead oxide > lead > lead sulfide > lead sulfate. Biodiesel production process is optimized according to an orthogonal design with biodiesel yield of 92 wt% obtained at AV of 9.6 mg KOH/g (82 wt% after 5 cycles). Biodiesel yield of 84 wt% is achieved at AV of 28.9 mg KOH/g with acidity of 0.18 mmol/g. Calcined blast furnace dust presents potential applications in the production of biodiesel from renewable oils with high AVs.

Related results were published in Renewable Energy:

YT Wang, WJ Cong, YN Zeng*, YQ Zhang, JL Liang, JG Li, LQ Jiang*, Z Fang*. Direct production of biodiesel via simultaneous esterification and transesterification of renewable oils using calcined blast furnace dust. Renewable Energy. 175, 1001-1011 (2021). https://doi.org/10.1016/j.renene.2021.05.013.

Blast furnace dust from steel industry is calcined for biodiesel production from renewable Jatropha oils with 92 wt% biodiesel yield and 5 cycles achieved. (来自于钢铁工业的高炉粉尘被煅烧后可用于催化小桐子油直接制备生物柴油,产率可达92 wt%,并循环5次)。

煅烧的高炉粉尘催化可再生油脂制备生物柴油

最近,王一同副教授 (女,华北理工大学冶金与能源学院) 和方真教授在国际学术期刊Renewable Energy (IF: 6.274,Q1) 发表题为“煅烧的高炉粉尘催化可再生油脂联合酯化和转酯化制备生物柴油”的研究性论文。

高炉粉尘通过高温煅烧后可制备固体酸碱两性材料,可催化高酸值小桐子油联合酯化和转酯化制备生物柴油。高炉粉尘在600和700 oC高温煅烧后晶相改变,粉尘中硫酸铅转化为氧化铅、硫化铅和铅颗粒,可以有效促进生物柴油生产。本研究首次发现氧化铅、硫化铅和铅颗粒具有很好抗酸能力,有效防止皂化现象发生,它们的催化活性顺序为:PbO > Pb > PbS > PbSO4。在正交实验优化的生产工艺条件下,催化酸值为9.6 mg KOH/g的小桐子油可获得92 wt%的产率,循环5次后仍可获得82 wt%的产率,催化酸值为28.9 mg KOH/g的小桐子油可获得84 wt%的产率。实验结果表明煅烧的高炉粉尘在高酸值油脂催化转化领域具有非常大的应用潜力。详情可见:

YT Wang, WJ Cong, YN Zeng*, YQ Zhang, JL Liang, JG Li, LQ Jiang*, Z Fang*. Direct production of biodiesel via simultaneous esterification and transesterification of renewable oils using calcined blast furnace dust. Renewable Energy. 175, 1001-1011 (2021). https://doi.org/10.1016/j.renene.2021.05.013.